- Complete SiC Solution

- Non-Destructive Advantage

- Microscopic Excellence

- AI-Powered Precision

- Unparalleled Accuracy

- Enhanced Efficiency

Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

Optical defect inspection is a non-destructive testing method that employs light to examine surfaces and materials for defects, irregularities, or contamination. This technology is widely used in various industries, including electronics, aerospace, automotive, and manufacturing, to ensure product quality and integrity.

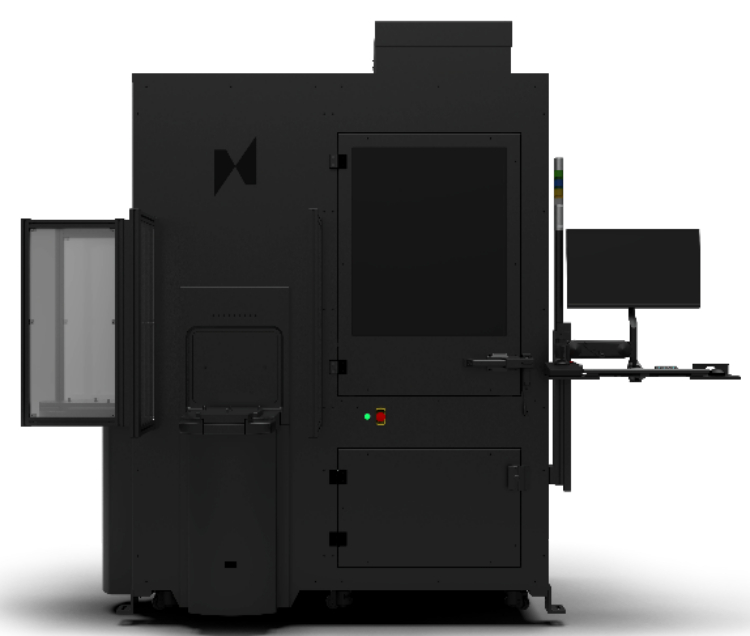

Nanotronics, a leading provider of optical defect inspection solutions, offers a range of advanced products that combine high-resolution imaging, artificial intelligence, and automation to deliver accurate, reliable, and efficient inspection capabilities. Their systems are designed to detect defects, measure dimensions, and analyse surface characteristics with exceptional precision, enabling manufacturers to identify and address issues early in the production process.

One of the key strengths of Nanotronics’ optical defect inspection products is the integration of machine learning algorithms, which enables the systems to adapt and improve their performance over time, reducing false alarms and increasing defect detection accuracy. These systems also offer high-speed inspection capabilities, minimising inspection times and enabling real-time process control.

By leveraging the cutting-edge technology in Nanotronics’ optical defect inspection products, manufacturers can enhance product quality, reduce scrap rates, and optimise overall production efficiency. This, in turn, contributes to increased competitiveness and profitability in today’s demanding market landscape.