- Advanced Cleaning Technology

- Comprehensive Cleaning Solutions

- Enhanced Performance and Yield

- Non-Disruptive Cleaning Process

- Longevity and Cost-Efficiency

- Uncompromising Quality and Reliability

Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

Probe, test, and burn-in products are essential tools in the semiconductor industry for assessing the performance, reliability, and quality of electronic components and devices. These products play a vital role in the manufacturing process, enabling manufacturers to identify and address defects or issues early in the production cycle and maintain high production yields.

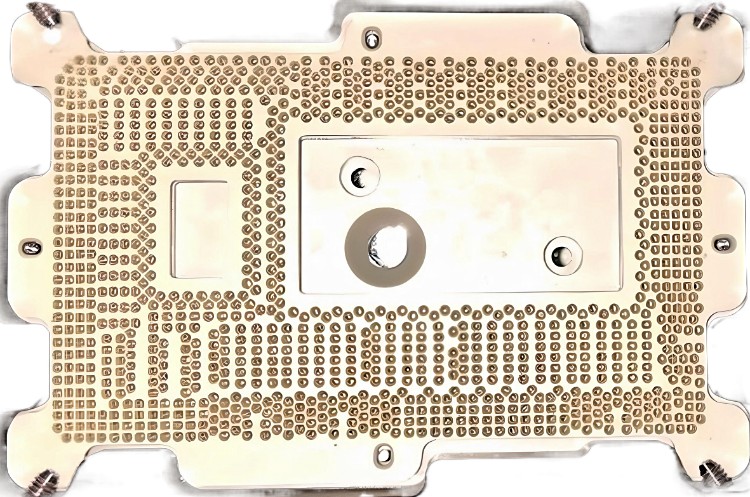

Probe products, such as wafer probe stations and probe cards, are used to test semiconductor wafers before they are diced and packaged, ensuring that individual die meet the required electrical and functional specifications. This step is critical for identifying and isolating defective die, preventing their incorporation into finished products.

Test products, which include automated test equipment (ATE), are utilised to test the functionality and performance of packaged semiconductor devices. ATE systems can perform a variety of tests, such as power-up, digital, and analog testing, to verify that devices meet design and quality standards.

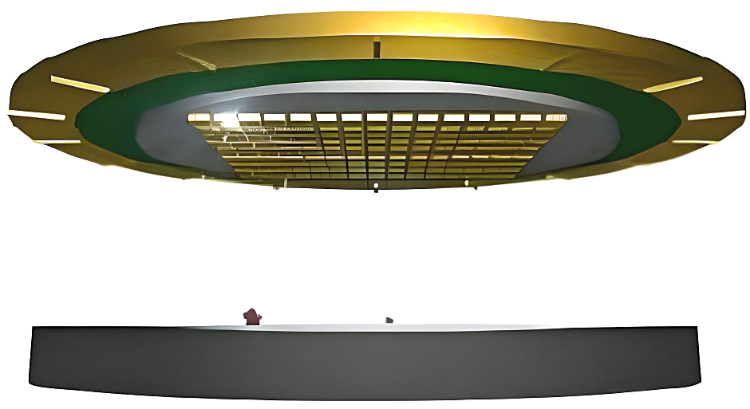

Burn-in products, like burn-in ovens and test sockets, subject semiconductor devices to accelerated aging conditions, such as elevated temperatures and electrical stress, to identify potential reliability issues and screen out early-life failures. This process helps to ensure the long-term stability and performance of electronic components.

By employing probe, test, and burn-in products, manufacturers can enhance product quality, reduce costs associated with defects, and ultimately improve customer satisfaction.