Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

How Hummink’s HPCaP Technology is Revolutionising Sustainable Electronics

In today’s rapidly evolving electronics industry, sustainability is more than just a trend—it’s a necessity. Manufacturers are under growing pressure to reduce waste, improve efficiency, and work towards net-zero goals. At SiSTEM Technology, we are proud to represent Hummink and their game-changing High Precision Capillary Printing (HPCaP) technology, which is transforming the way electronic components are manufactured, repaired, and optimised for a greener future.

The Challenge: Sustainability in Electronics Manufacturing

The electronics industry is a major contributor to global carbon emissions, energy consumption, and material waste. Traditional manufacturing techniques, such as photolithography, involve multiple energy-intensive steps, excessive chemical usage, and significant material waste. Additionally, electronic waste (e-waste) continues to pile up, with millions of tons discarded every year. The need for sustainable and efficient alternatives has never been more critical.

The Solution: Hummink’s HPCaP Technology

Hummink’s High Precision Capillary Printing (HPCaP) introduces a groundbreaking approach to electronics manufacturing, offering a precise, scalable, and environmentally friendly alternative to traditional methods. Here’s why it’s a game-changer:

1. Near-Zero Material Waste

HPCaP employs capillary forces for ink deposition, ensuring that every drop of material is utilised with extreme precision. Unlike conventional photolithography, where significant amounts of material are wasted in the etching and coating process, HPCaP reduces waste to almost zero, making it one of the most resource-efficient solutions available.

2. Lower Energy Consumption

Traditional semiconductor and electronics fabrication methods require high energy input due to complex multi-step processes. Hummink’s HPCaP can:

- Reduce production steps from seven to one

- Cut processing time from 16 hours to just 30 minutes

- Lower overall power consumption in manufacturing. These efficiencies contribute directly to lower carbon emissions and reduced operational costs for manufacturers.

3. Repair Instead of Replace: Extending Product Lifespan

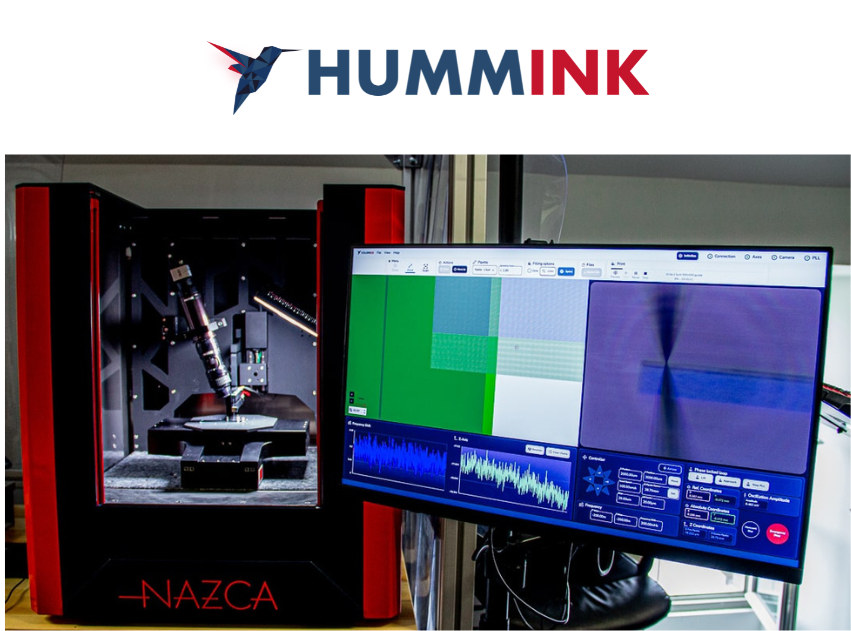

E-waste is a growing concern, with millions of devices discarded due to minor faults. Hummink’s NAZCA printer allows for precise reprinting of conductive traces, enabling the repair and restoration of damaged electronic circuits, OLED displays, and semiconductors. This supports a circular economy, where products are reused and repaired instead of being replaced, reducing waste and demand for new raw materials.

4. Sustainable Flexible Electronics for the Future

HPCaP enables high-resolution printing on diverse substrates, including flexible and lightweight materials such as PET foils and Kapton films. This advancement is crucial for industries developing wearable electronics, smart sensors, and next-generation flexible devices. By supporting energy-efficient and recyclable materials, Hummink’s technology aligns perfectly with the green electronics movement.

5. Supporting the Net-Zero Agenda

Many industries, from automotive to aerospace and medical technology, are working towards Net-Zero carbon goals. Hummink’s HPCaP technology helps manufacturers cut emissions and optimise processes, making sustainable manufacturing more accessible and practical. By reducing energy-intensive steps and eliminating waste, HPCaP contributes directly to carbon footprint reduction.

At SiSTEM Technology, we specialise in bringing cutting-edge, sustainable semiconductor solutions to the industry. Representing Hummink aligns with our commitment to delivering innovative, energy-efficient, and sustainable manufacturing technologies. By partnering with Hummink, we provide manufacturers with a transformative solution that enhances precision, reduces waste, and promotes environmentally responsible production.

Contact us today to learn more about this amazing technology.