Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

Nanotronics Launches Revolutionary AI Model and Cost-Effective Inspection Solutions

Nanotronics is transforming the manufacturing landscape with the introduction of its state-of-the-art AI model and two groundbreaking hardware products. Supported by Founders Fund and trusted by major industry players, including four of the five FAANG companies and two of the top three global semiconductor manufacturers, Nanotronics is leading the charge in AI-driven manufacturing efficiency.

GEN V AI: Redefining Manufacturing Intelligence

The latest innovation from Nanotronics, GEN V AI, comes pre-loaded with ten years’ worth of defect data from premier manufacturing operations worldwide. Leveraging the same advanced transformer technology that powers ChatGPT, this AI model facilitates immediate automation of quality inspections. By eliminating the need for lengthy and costly AI training processes, GEN V AI drastically reduces costs and accelerates training periods. This breakthrough allows manufacturers of all sizes to surpass traditional methods and achieve unprecedented efficiency, making AI-driven quality inspection accessible to all.

nSpec LS Air: Revolutionising Quality Inspection for All Industries

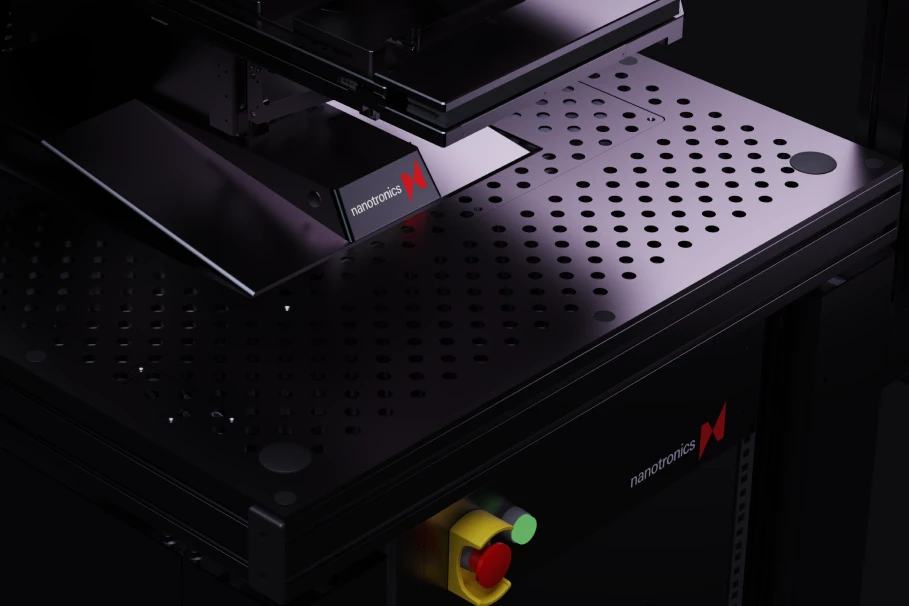

The nSpec LS Air model brings sophisticated quality inspection capabilities combined with pre-trained AI to any factory, enabling rapid automation of inspection processes. This versatile product serves a wide range of sectors, including aerospace, pharmaceuticals, and electronics. It provides manufacturers with the tools needed to enhance productivity without prohibitive costs, democratising advanced quality inspection.

nSpec PS Air: Precision Inspection for the Semiconductor Industry

Tailored for the semiconductor industry, the nSpec PS Air incorporates the same cutting-edge technology as the LS Air but is optimised for wafer inspection. This model offers semiconductor fabs a cost-effective solution to automate quality inspection, allowing them to scale operations efficiently and address yield challenges. The nSpec PS Air integrates seamlessly into existing workflows, providing a comprehensive solution for rapid and precise inspection.

Matthew Putman, CEO of Nanotronics, underscores the transformative impact of these innovations: “Our GEN V AI and new nSpec Air models are not just incremental improvements; they are exponential force multipliers. They empower factories with unparalleled efficiency and accuracy at a fraction of the cost. This is a pivotal moment for global manufacturing, and we are thrilled to lead the charge.”

Already deployed in hundreds of factories worldwide, these advancements signal a significant shift in the production of complex hardware. The GEN V AI and nSpec models integrate seamlessly with existing manufacturing processes, offering an out-of-the-box solution that leverages Nanotronics’ extensive decade-long data repository. This system translates vast data points into actionable insights, enabling manufacturers to correct production flaws in real-time and predict future errors, fostering an autonomous factory environment. This technological leap drives up yields, reduces waste, and promotes sustainable practices across the manufacturing industry.

Matthew Putman highlights the broader impact: “Many local manufacturers have watched from the sidelines as conglomerates and foreign competitors adopted AI systems to streamline efficiency. Given the scale and margins of many factories in America’s heartland, most AI solutions have been cost-prohibitive. Now, we’re enabling any manufacturer, regardless of scale, to fully embrace the Age of AI—detecting defects earlier in the process and refining their entire production lines.”

Nanotronics’ latest innovations are democratising advanced manufacturing technology, making high-efficiency, AI-driven quality inspection accessible to factories of all sizes worldwide. SiSTEM Technology is excited to be part of this transformative journey.