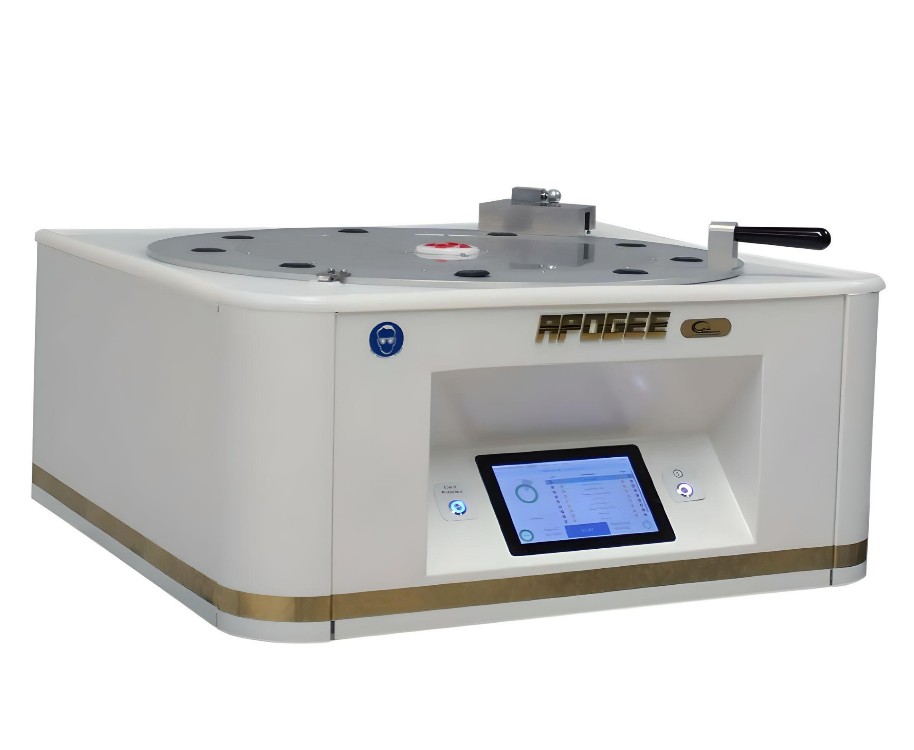

Apogee 450 Spin Coater

Spin Coater for Advanced Coating Applications

The Cost Effective Equipment Apogee 450 Precision Spin Coater redefines the standards of spin coating technology, offering unparalleled performance and innovation for your wafer processing. Designed to cater to the needs of high-precision applications, it is the ideal choice for handling 300 mm wafers and LCD squares up to 14” × 14”, ensuring exceptional results with every use.

Space-Efficient and Powerful

Despite its compact footprint, the Cost Effective Equipment Apogee 450 is a powerhouse, featuring the highest horsepower drive system of any spin coater in its class. This heavy-duty drive spin coater combines precise spin speed control with high torque drive for aggressive acceleration, delivering track-quality performance in a space-saving design.

User-Friendly Interface

Ease of use is at the forefront with a full-colour, 7-inch touch screen display. The intuitive graphical user interface (GUI) is alphanumeric-capable, simplifying the setup and execution of complex coating processes.

Advanced Chemical Compatibility

The Apogee Spin Coater boasts a high-density polyethylene (HDPE) spin bowl, ensuring maximum chemical resistance. Coupled with an optional nitrogen purge for creating an inert spin environment, it offers unparalleled process flexibility and repeatability.

Enhanced Design Features

The Cost Effective Equipment Apogee 450 Spin Coater comes with an enhanced lid-lift assist feature for effortless access, supporting its durable benchtop and optional flange/deck mountable configurations. The optional Cost Effective Equipment X-PRO-II Workstation further augments its utility by integrating a stand-alone cabinet with an upper exhaust enclosure for effective fume control during processes.

Unmatched Control

Offering a virtually unlimited number of user-defined recipe program steps and a 0.1-second resolution for step times, the Apogee 450 Spin Coater empowers users to achieve precise coating processes. Spin speeds of up to 6,000 rpm and variable acceleration rates cater to a broad range of substrate sizes and types.

Seamless Integration

With USB/Ethernet connectivity, the Apogee Spin Coater 450 facilitates easy uploading and downloading of process parameters. DataStream technology ensures that process data is efficiently managed, providing a seamless interface for process control and optimisation.

Exceptional Accuracy

The Cost Effective Equipment Apogee 450 is engineered for precision, offering spin speed repeatability and spin speed resolution of less than 0.2 rpm. It can accommodate substrates up to 450 mm round and 14” x 14” square, ensuring consistent, high-quality coatings across a wide range of applications.

- 0.1-second resolution for step times (9,999.9 seconds maximum step time)

- Spin speed: 6,000 rpm

- Spin speed acceleration

- 0 to 30,000 rpm/s unloaded

- 0 to 23,000 rpm/s with a 300-mm substrate

- 0 to 3,000 rpm/s with a 350mm x 6mm round recessed spin chuck

- 0 to 400 rpm/s with a 14” × 14” × 1.1 mm photomask in a recessed chuck

Built for Durability

An indirect drive system shields the spin motor from process chemicals and solvents, enhancing the coater’s longevity and reliability. Vacuum and lid interlocks add an extra layer of safety and operational security.

Unrivalled Support

The Apogee 450 Spin Coater comes with a 1-year full warranty, backed by free remote technical support for the life of the product. Cost Effective Equipment’s commitment to excellence extends to offering application process assistance, ensuring that you have the support you need, when you need it.

Specifications

Dimensions: 27-5/8” W × 30-3/4” D × 15-1/2” H*, with a machine weight of 115 lb (52.2kg)

*H is with lid closed. With lid open H is 30-1/4” (76.9cm)

The Cost Effective Equipment Apogee 450 Precision Spin Coater is a comprehensive solution designed to elevate the precision, efficiency, and quality of your spin coating operations. Whether for research and development, or production, it offers the advanced features, reliability, and support needed to push the boundaries of spin coating technology. The Apogee 450 Spin Coater can also be inserted into the fully-customisable Cost Effective Equipment X-Pro II Workstation if you are looking for an integrated process station including spin developer(s) and/or bake plate(s).

Get a quote today for the Cost Effective Equipment Apogee 450 Spin Coater to see how where innovative design meets unparalleled precision and durability. Alternatively, contact us if you have any questions before requesting a quote to to discover how this state-of-the-art equipment can revolutionise your coating processes and help you achieve exceptional results.